Product

EGRT

Positioner

-

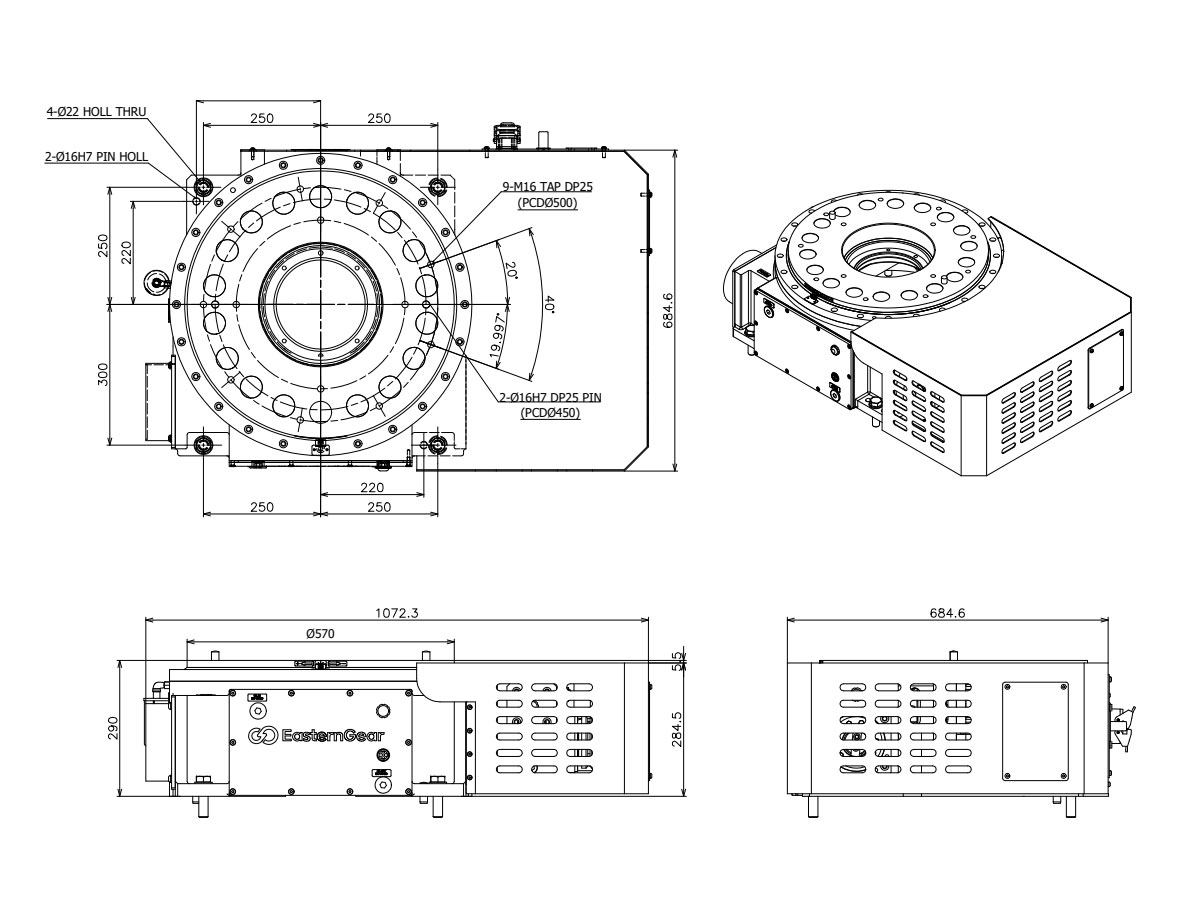

With high-torque indexing performance, this rotary table delivers precise positioning control and powerful drive capabilities. Equipped with globoid worm gear technology in a compact structure, it offers an automation solution optimized for robot integration and smart factory environments.

◆ Key Features

-

±60 arcsec repeatability for high-precision welding processes

-

Simultaneous surface contact structure based on globoid worm gear ensures high torque transmission

-

Maximum allowable torque: 8,000 kg·m

-

Supports ±360° infinite rotation

-

Slim housing and high-rigidity body design for space-constrained equipment

-

Available models supporting payloads from 2.5 to 7.5 tons (EGRT-2500 / 5000 / 7500)

-

Custom mounting and robot communication interface options available

◆ Applications

-

Automotive body welding lines

-

Industrial collaborative robot automation cells

-

High-precision indexing systems in smart factories

-

Multi-axis motion control systems

-

Assembly lines for heavy equipment and energy facility components

-

| Contents | EGRT-2500 | EGRT-5000 | EGRT-7500 |

|---|---|---|---|

| Moter (kW) | 3.5 | 5 | 5 |

| Reduction Ratio | 1:165 | 1:180 | 1:234 |

| Payload Capacity (kg) | 2,500 | 5,000 | 7,500 |

| Degrees of Freedom (axes) | 1 | 1 | 1 |

| Drive Type | BERREL CAM - WORM GEAR | BERREL CAM - WORM GEAR | BERREL CAM - WORM GEAR |

| Max Rotation Angle (°) | ±360 | ±360 | ±360 |

| Max Rotation Speed (°/s) | 74 | 67 | 44 |

| Max Operating Speed (at 2000rpm)(rpm/min) |

12.3 |

11 |

8.6 |

| Allowable Output Torque (kg·m) | 5,000 | 6,000 | 8,000 |

| Allowable Moment of Inertia (kg·m²) | 2,290 | 3,950 | 6,870 |

| Repeatability Accuracy (arcsec) | ±60 | ±60 | ±60 |

| Unit Weight (kg) | 432 | 432 | 432 |

| Center Hole Diameter (mm) | Ø190 | Ø190 | Ø190 |

| Work Area W*L(mm) | 1200*2400 | ||

| Operating Temperature (°C) | 0 ~ 45 (273 ~ 318K) | ||

| Controller Model | Hi5 / Hi5a | ||

| Color | Light Gray RAL7035 (Standard) / Color not customizable | ||

🛞 High-Torque Rotary Table for Heavy-Duty Robotic Welding (EasternGear EGRT Positioner Series)

✅ A New Standard in Precision Positioner Systems

The EGRT Series from EasternGear is a high-torque rotary table optimized for heavy-duty robotic welding automation.

Available in three models—EGRT-2500, EGRT-5000, and EGRT-7500—this lineup supports payloads of 2.5 tons, 5 tons, and 7.5 tons respectively, and is engineered to meet the demands of high-precision applications across diverse industrial environments.

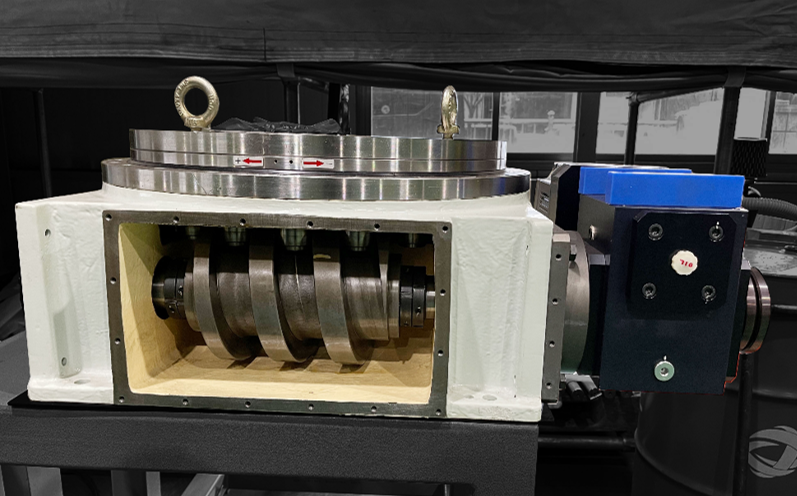

✅ Core Technology: Barrel-Cam Type Globoid Worm Gear System

The defining feature of the EGRT series is its globoid (barrel-type) worm gear drive system.

Unlike conventional cylindrical worm gears, the globoid gear enables wide surface contact, allowing for higher torque transmission, enhanced durability, precise motion control, and compact form factors—all in one.

This makes it especially effective for integration with precision welding equipment and collaborative robotics.

✅ Powerful Torque Meets Precision Control

The EGRT Series supports up to 8,000 kg·m of torque with a repeatability of ±60 arcseconds.

It is ideally suited for precision spot welding, automated fixture positioning, and robotic arm synchronization, while the ±360° continuous rotation supports flexible and dynamic process design.

✅ Optimized Design for Smart Factories

Despite its slim housing, the EGRT series maintains a high-rigidity structure, making it ideal for high-performance welding automation in tight spaces.

It contributes to enhanced productivity and efficiency in multi-axis control systems within the automotive, industrial robotics, and heavy machinery sectors.

✅ Design Flexibility with Complete Turnkey Solutions

EasternGear's globoid worm technology ensures low backlash and stable performance even under high torque.

This provides exceptional design flexibility across various use cases while improving system reliability and longevity in complex robotic setups and industrial production lines.

Backed by decades of worm drive expertise, the EGRT series delivers not just a rotary table, but a next-generation high-precision robotic automation solution.