Project

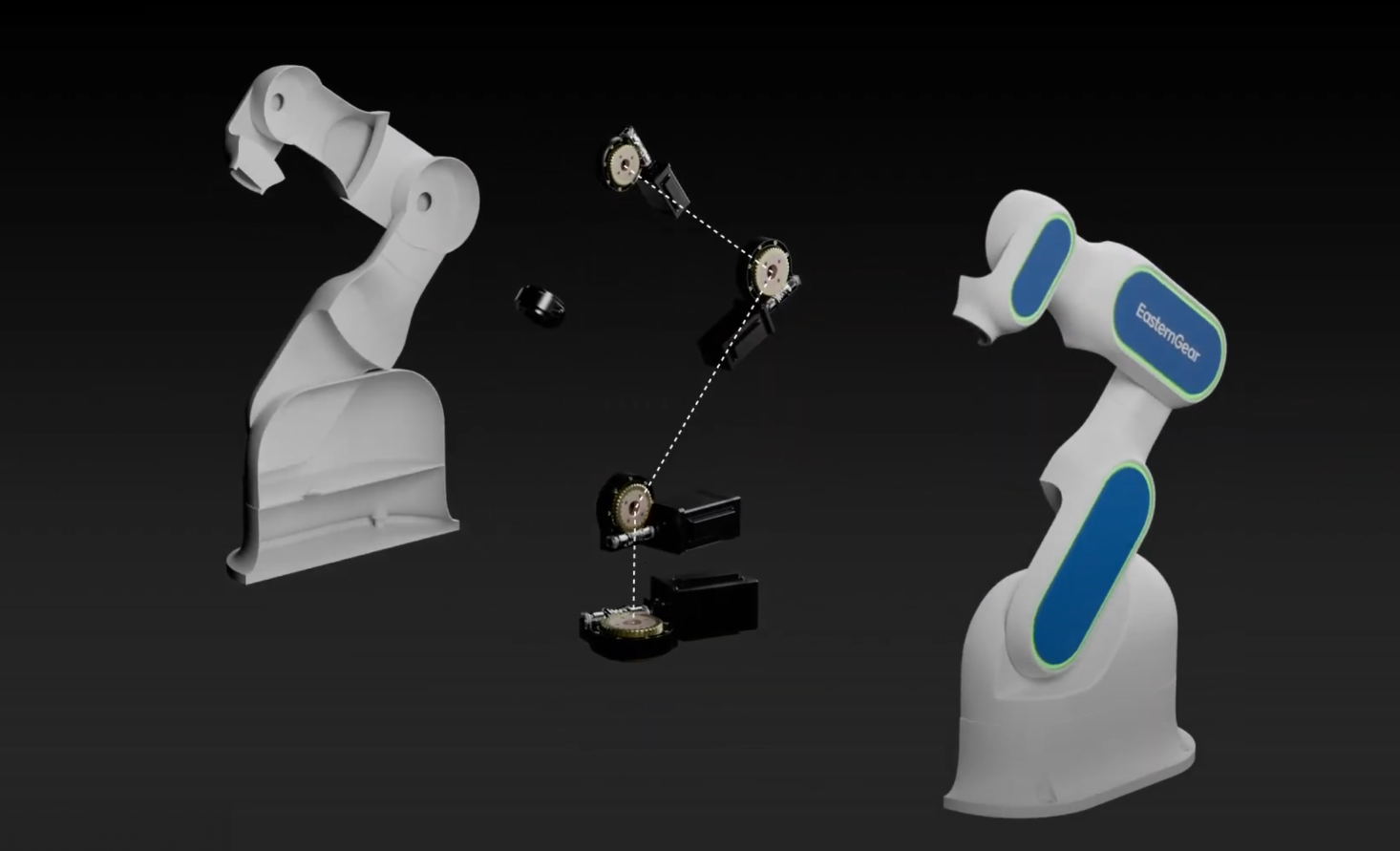

Development of a 5 DoF collaborative robot arm

✔️Robot Reducer and Robotic Arm Development Utilizing Globoid Worm Gear

To address persistent issues of technological centralization and monopoly sales by major companies and countries in the high-tech industrial market, EasternGear has undertaken the development of robot reducers, a core component of robotic joints.

While Harmonic Drive and RV reducers have dominated the robot reducer market until recently, diversification in robotic structures has increased demand for robot reducers that are lighter, simpler, yet capable of precise control.

In response to this market trend, our EasternGear Research Institute has researched and developed an innovative robot reducer based on Globoid Worm Gear (Hourglass Worm Gear) technology, surpassing conventional worm reducers.

Through this project, we successfully developed a robotic arm applying an innovative reducer that achieves both cost reduction and enhanced payload capacity compared to existing similar-specification products. This serves as an excellent case demonstrating the superior performance of the Globoid Worm Gear reducer.

✔️Features of EasternGear’s 5-Axis Articulated Robotic Arm

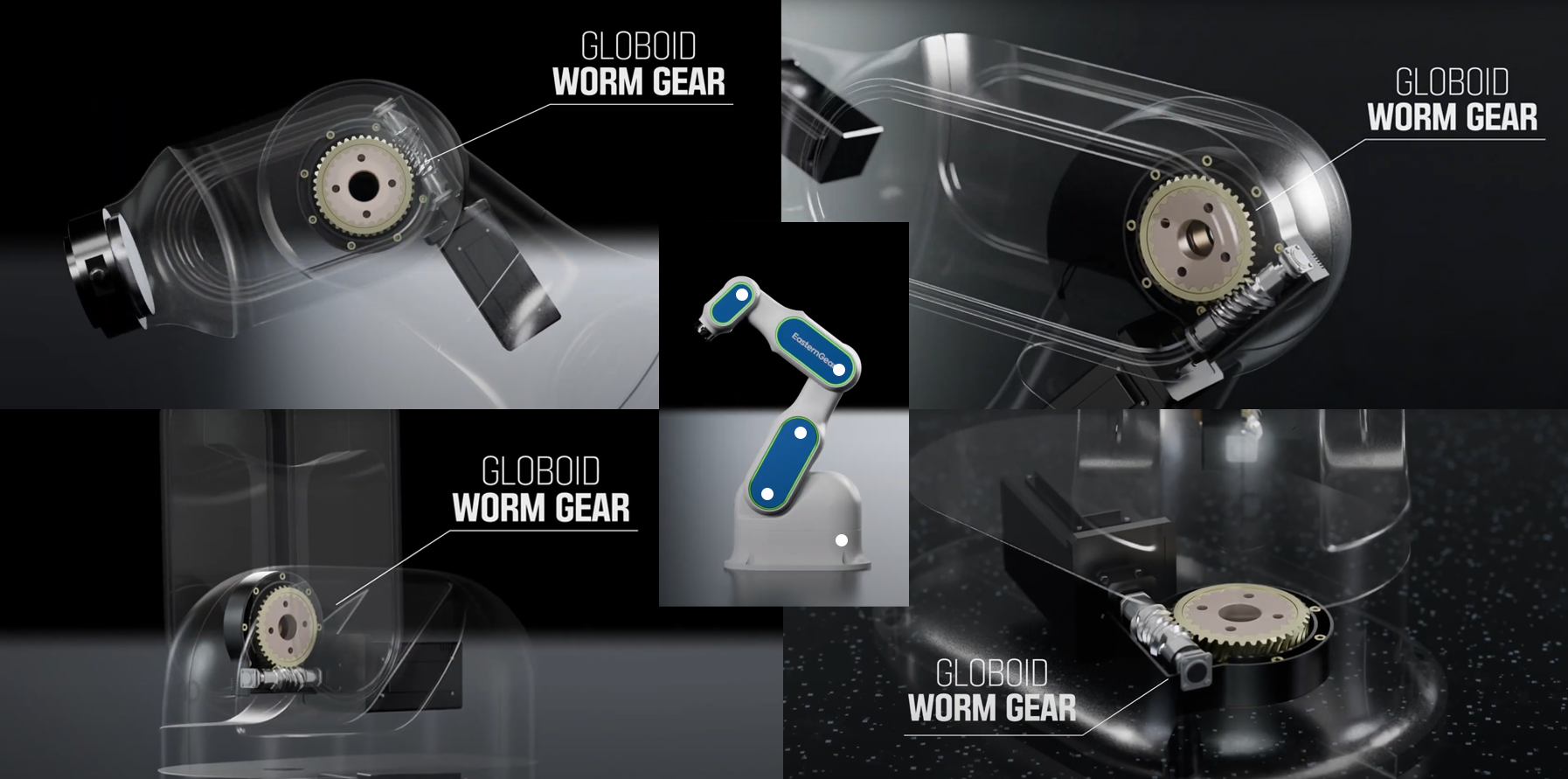

EasternGear's 5-axis articulated robotic arm is equipped with gears at each joint, providing higher maximum torque and enhancing precision and accuracy. From the base to the end effector, every joint utilizes a globoid (hourglass) worm gear.

One notable feature of the globoid worm gear is its built-in self-locking capability (anti-backdrive), significantly improving security and safety. The robotic arm offers an operational reach of 1400 mm (55.18 inches) and is capable of handling payloads of up to 20 kg (44 lbs).

Below is an actual operating demonstration video of the 5-axis articulated robotic arm.

✔️SPEC

| 항목 | 스펙 |

| Controlled Axes (Number of Axes) | 5-Axis Articulated |

| Payload Capacity (kg) | 20kg or more |

| Working Radius (mm) | 1400mm |

| Repeatability (mm) | ±0.12mm |

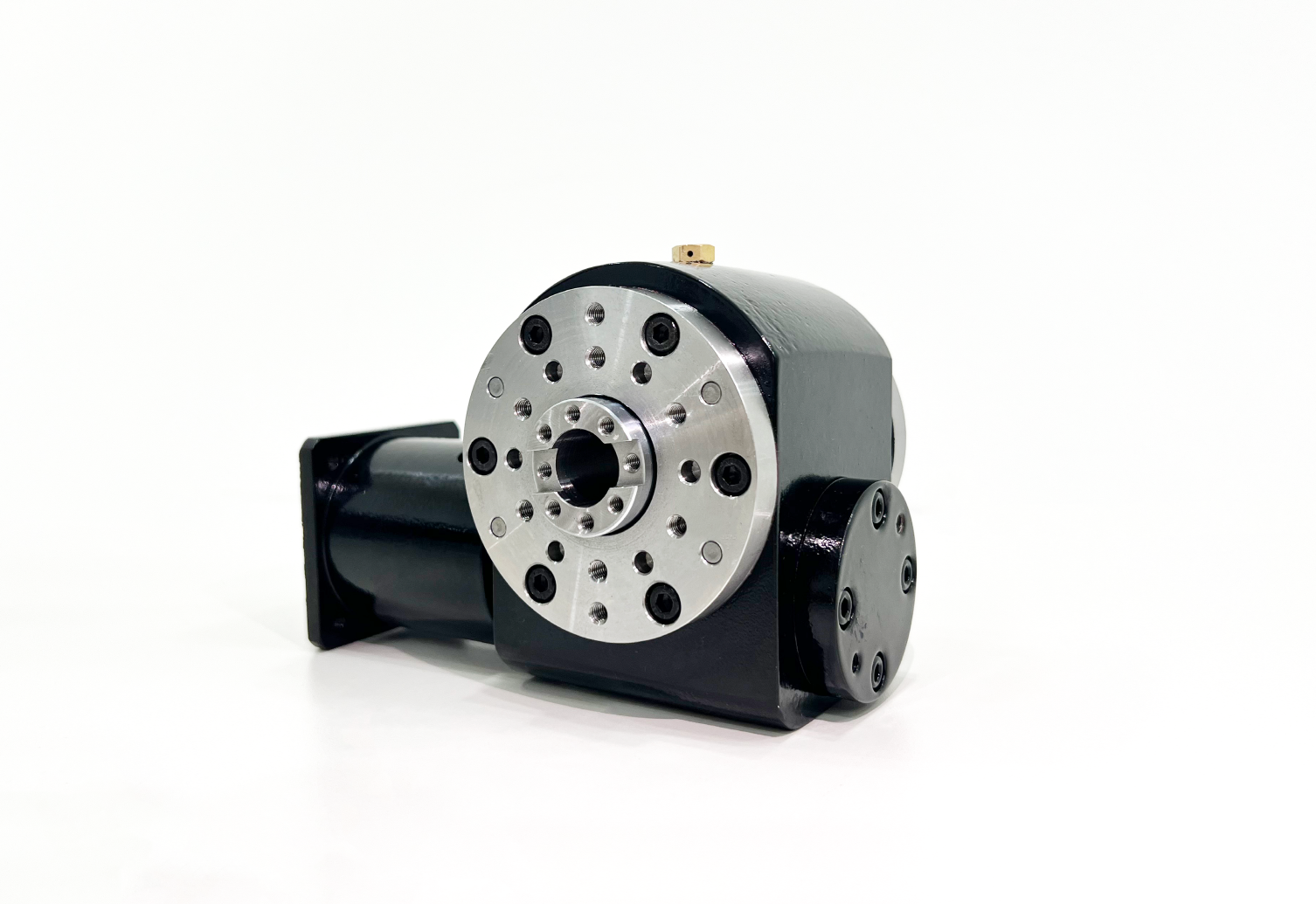

✔️Robot Reducer

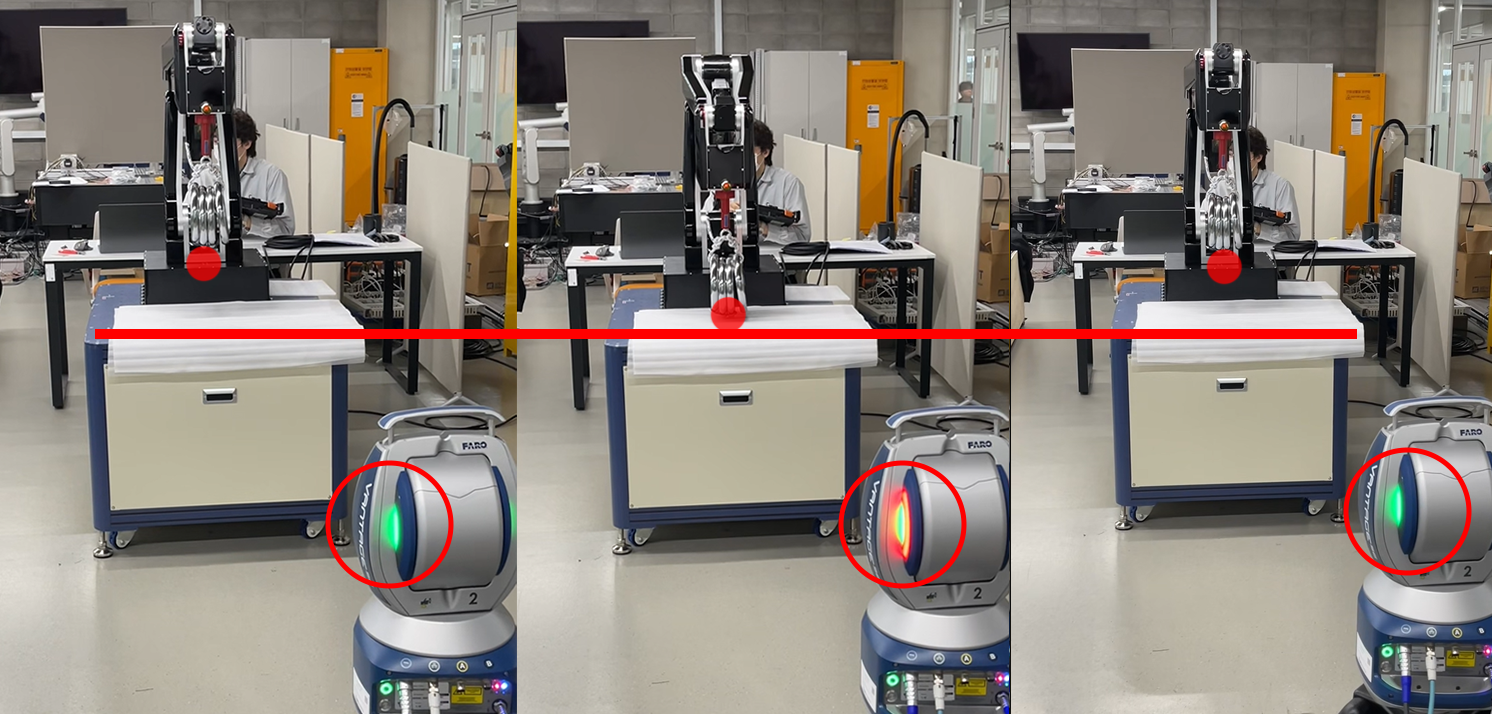

✔️Robotic Arm Repeatability Test

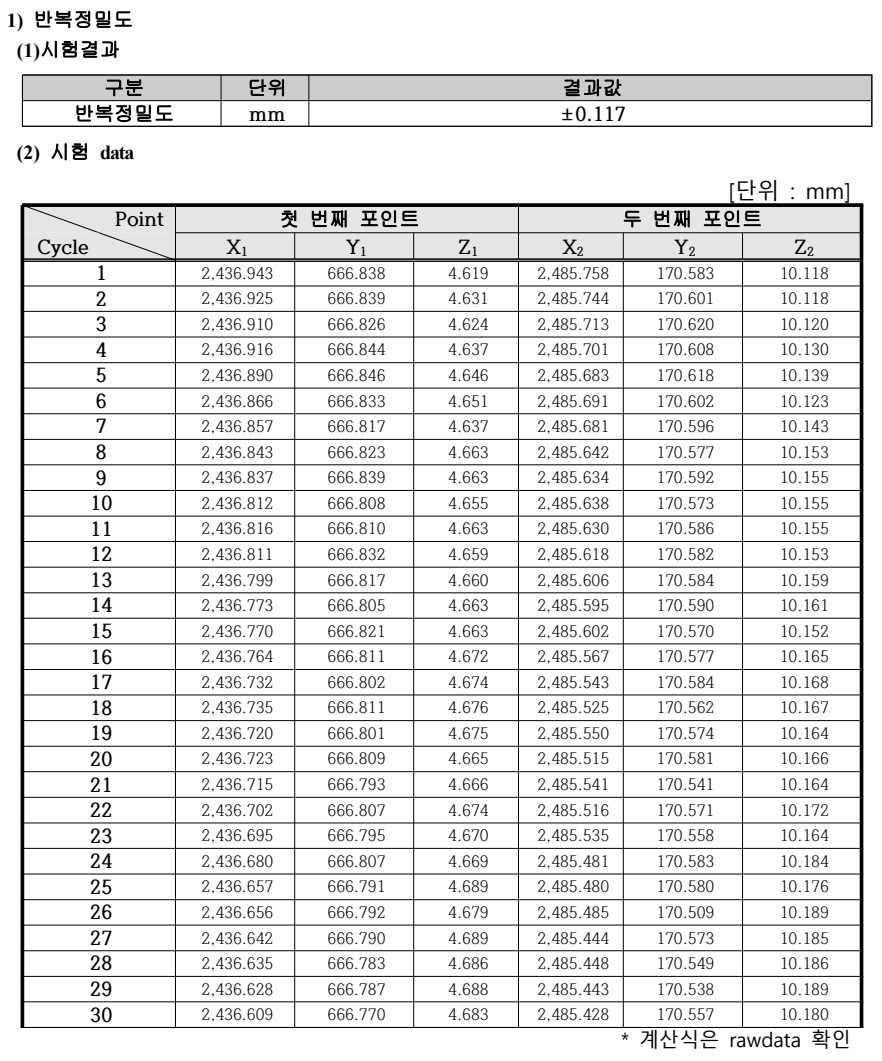

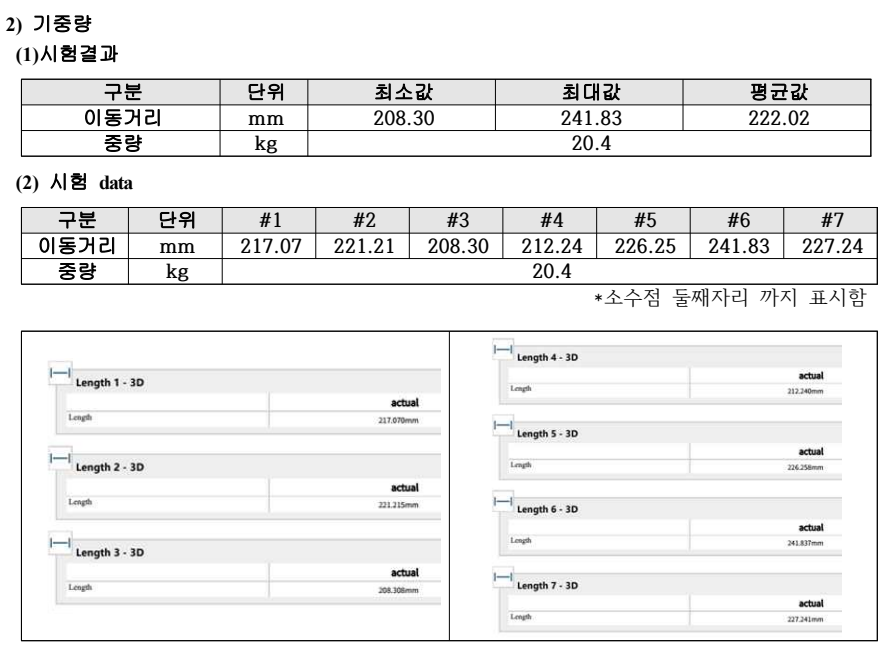

This is a repeatability and payload capacity test conducted by the Korea Institute of Robotics and Technology Convergence (KIRO). The test procedures and results are as follows.

[Test Procedures]

-

Repeatability

-

Attach an SMR measurement sensor to the end effector.

-

Use a laser tracker to measure repeatability over 30 round-trip movements to designated points, following the robot industry standard KS B ISO 9283:2011.

-

Payload Capacity

-

Verify the load weight using a scale.

-

Attach the verified load weight to the robot’s end effector.

-

Measure the robot’s movement distance using a laser tracker.

[Test Results]

✔️Additional Condition Tests

✔️Promotional Video